The process and equipment design of multi-modular NPPs is nearly the same as that of single modular NPPs. The major difference between the multi-modular and single modular NPPs focuses on the control and operation that is mainly provided by the CCS. The multi-modular coordinated control is the mechanism playing a central role in the realization of multi-modular scheme, giving the plant responses in normal and abnormal scenarios. In this section, the coordination mechanism inside a single reactor module and between two modules are proposed, giving the CCS design of HTR-PM plant.

Coordinated control of a single reactor module

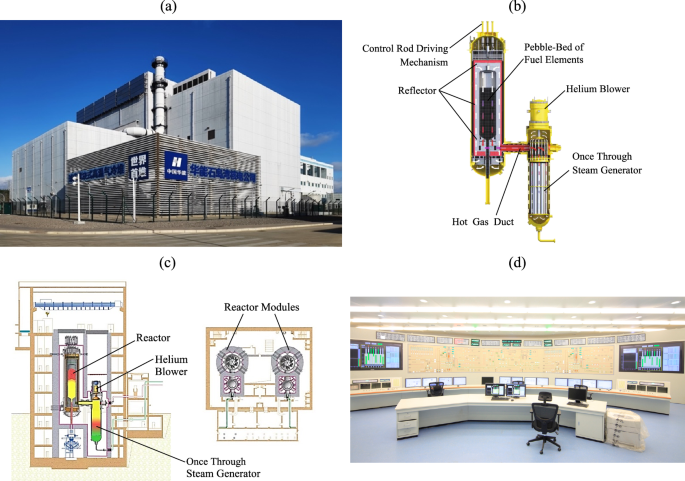

As illustrated in Fig. 2, the cold helium is first pressurized by the helium blower, before being directed to the reactor along the annular cold gas duct. Once it is blended within the bottom region of the reactor, the cold helium ascends through the boreholes in the side reflector from to the upper section, subsequently circulating downwards through the pebble-bed reaching temperatures near 700 °C at the pebble bed’s outlet18. The bypassed cold helium is collected and combined with the hot helium flowing from the pebble-bed inside the hot gas plenum located in the bottom reflector. The mixed hot gas, exceeding 550 °C, is guided to the primary side of OTSG via the hot gas duct, transforming the secondary feedwater flow to the superheated steam flow. The coordinated control within a reactor module is designed to regulated the tightly coupled process variables including neuron flux, helium temperature and steam temperature of an individual mHTGR module, ensuring the closed-loop stability in the scenarios of power-level maintaining and maneuvering. Similar to36,37,38, the dynamic model of a reactor module for control design can be written as:

$$\left\{\begin{array}{c}\varLambda {\dot{n}}_{{\rm{r}}}=-\beta ({n}_{{\rm{r}}}-{c}_{{\rm{r}}})+{n}_{{\rm{r}}}[{G}_{{\rm{r}}}{z}_{{\rm{r}}}-{\alpha }_{{\rm{R}}}({T}_{{\rm{R}}}-{T}_{{\rm{R}},{\rm{m}}})],\\ {\dot{c}}_{{\rm{r}}}=\lambda ({n}_{{\rm{r}}}-{c}_{{\rm{r}}}),\hfill\\ {\mu }_{{\rm{R}}}{\dot{T}}_{{\rm{R}}}={P}_{0}{n}_{{\rm{r}}}-{\varOmega }_{{\rm{P}}}({T}_{{\rm{R}}}-{T}_{{\rm{P}}}),\hfill\\ {\mu }_{{\rm{H}}}{\dot{T}}_{{\rm{H}}}={\varOmega }_{{\rm{P}}}({T}_{{\rm{R}}}-{T}_{{\rm{P}}})-{\varOmega }_{{\rm{S}}}({T}_{{\rm{P}}}-{T}_{{\rm{S}}}),\hfill\\ {\mu }_{{\rm{S}}}{\dot{T}}_{{\rm{S}}}={\varOmega }_{{\rm{s}}}({T}_{{\rm{P}}}-{T}_{{\rm{S}}})-2{M}_{{\rm{S}}}({T}_{{\rm{S}}}-{T}_{\mathrm{Sin}}),\hfill\\ {\dot{z}}_{{\rm{r}}}={v}_{{\rm{r}}},\hfill\end{array}\right.$$

(1)

where P0 is the rated thermal power of reactor, Λ is the prompt neutron generation time, λ is the averaged decay constant of delayed precursors, β is the fraction of delayed neutrons, nr is the normalized neutron flux, cr is the normalized concentration of delayed neutron precursors, Gr is the control rod differential worth, zr is the total displacement of control rods, vr is the control rod speed, TR is the average temperature of reactor core with TR,m as its initial steady value, αR is the reactivity feedback coefficient of reactor core temperature, TH is the average primary helium temperature, TS is the average secondary coolant temperature of the steam generator, TSin is the coolant temperature at the secondary inlet of steam generator, MS is the secondary heat capacity flow, μR, μH and μS are the total heat capacities of reactor core, primary helium and secondary coolant respectively, ΩP and ΩS are respectively the heat transfer coefficient between the helium and pebble-bed and that between the two sides of steam generator.

Define δnr = nr–nr0, δcr = cr–cr0, δρr = ρr–ρr0, δTR = TR–TR0, δTH = TH–TH0, δTS = TS–TS0 and δTSin = TSin–TSin0, where nr0, cr0, ρr0, TR0, TH0, TS0 and TSin0 are the setpoints of process variables nr, cr, ρr, TR, TH, TS and TSin respectively. In addition, as δTSin is determined by the operational state of the conventional island, it is assumed that δTSin = 0 in the coordinated control design. Moreover, since the helium flowrate can be adjusted by the rotation rate of the primary helium blower, it is not loss of generality to assume that

$${\rm{\delta }}{\varOmega }_{{\rm{S}}}={\varOmega }_{{\rm{S}}}-{\varOmega }_{{\rm{S0}}}={\varLambda }_{{\rm{S}}}{\rm{\delta }}{G}_{{\rm{P}}}$$

(2)

where δGP is the variation of the primary helium flowrate with respect to the setpoint, ΩS0 is the value of heat transfer coefficient ΩS at the concerned setpoint, ΛS is a positive constant given by

$${\varLambda }_{{\rm{S}}}={\frac{\partial {\varOmega }_{{\rm{S}}}}{\partial {G}_{{\rm{P}}}}\Big|}_{{G}_{{\rm{P}}}={G}_{{\rm{p0}}}}$$

(3)

with GP0 being the setpoint of primary helium flowrate.

Further, define

$${\bf{x}}={[{x}_{i}]}_{i=1}^{5}={[\begin{array}{ccccc}{\rm{\delta }}{n}_{{\rm{r}}} & {\rm{\delta }}{c}_{{\rm{r}}} & {\rm{\delta }}{T}_{{\rm{R}}} & {\rm{\delta }}{T}_{{\rm{H}}} & {\rm{\delta }}{T}_{{\rm{S}}}\end{array}]}^{{\rm{T}}}$$

(4)

$$\xi={\rm{\delta }}{z}_{{\rm{r}}}$$

(5)

$${\bf{u}}={[\begin{array}{cc}{u}_{1} & {u}_{2}\end{array}]}^{{\rm{T}}}={[\begin{array}{cc}{v}_{{\rm{r}}} & {\rm{\delta }}{G}_{{\rm{P}}}\end{array}]}^{{\rm{T}}}$$

(6)

and then the nonlinear state-space model for control design can be written as

$$\left\{\begin{array}{c}\dot{{\bf{x}}}={\bf{f}}({\bf{x}})+{{\bf{g}}}_{1}({\bf{x}})\xi+{{\bf{g}}}_{2}({\bf{x}}){u}_{2},\\ \dot{\xi }={u}_{1},\hfill\\ {\bf{y}}={[\begin{array}{ccc}{x}_{1} & {x}_{4} & {x}_{5}\end{array}]}^{{\rm{T}}},\hfill\end{array}\right.$$

(7)

where

$${\bf{f}}({\bf{x}})=\, \left[-\frac{\beta }{\varLambda }({x}_{1}-{x}_{2})-\frac{{\alpha }_{{\rm{R}}}}{\varLambda }({n}_{{\rm{r0}}}+{x}_{1}){x}_{3} \quad \lambda ({x}_{1}-{x}_{2}) \quad -\frac{{\varOmega }_{{\rm{P}}}}{{\mu }_{{\rm{R}}}}({x}_{3}-{x}_{4})\right. \\ \quad+\left.\frac{{P}_{0}}{{\mu }_{{\rm{R}}}}{x}_{1} \quad {\frac{{\varOmega }_{{\rm{P}}}}{{\mu }_{{\rm{P}}}}({x}_{3}-{x}_{4})-\frac{{\varOmega }_{{\rm{S0}}}}{{\mu }_{{\rm{P}}}}({x}_{4}-{x}_{5}) \quad \frac{{\varOmega }_{{\rm{S0}}}}{{\mu }_{{\rm{S}}}}({x}_{4}-{x}_{5})-\frac{2{M}_{{\rm{S}}}}{{\mu }_{{\rm{S}}}}{x}_{5}}\right]^{{\rm{T}}},$$

(8)

$${{\bf{g}}}_{1}({\bf{x}})={\left[\frac{{G}_{{\rm{r}}}}{\varLambda }({n}_{{\rm{r0}}}+{x}_{1}) \quad {{\bf{O}}}_{1\times 4}\right]}^{{\rm{T}}}$$

(9)

$${{\bf{g}}}_{2}({\bf{x}})={\left[\begin{array}{ccc}{{\bf{O}}}_{1\times 3} & -\frac{{\varLambda }_{{\rm{S}}}}{{\mu }_{{\rm{P}}}}({T}_{{\rm{P0}}}-{T}_{{\rm{S0}}}) & \frac{{\varLambda }_{{\rm{S}}}}{{\mu }_{{\rm{P}}}}({T}_{{\rm{P0}}}-{T}_{{\rm{S0}}})\end{array}\right]}^{{\rm{T}}}$$

(10)

x and ξ are state-variables, u is the control input, and y is the measurement output. The following proposition gives the output-feedback coordinated control of a single reactor module, and the corresponding sufficient condition for globally asymptotic closed-loop stability.

Proposition 1

Consider nonlinear system (7) giving the dynamics of a mHTGR-based reactor module. The output feedback control given by

$$\left\{\begin{array}{c}{u}_{1}=-{k}_{{\rm{D1}}}{\dot{x}}_{1}-{k}_{{\rm{D2}}}{\dot{x}}_{4}-{\dot{\zeta }}_{1}-{\dot{\zeta }}_{2}\hfill\\ {u}_{2}=-{[{\varLambda }_{{\rm{S}}}({T}_{{\rm{P0}}}-{T}_{{\rm{S0}}})]}^{-1}{\varOmega }_{{\rm{S0}}}({k}_{{\rm{P3}}}{x}_{5}+{\zeta }_{3})\hfill\\ {\dot{\zeta }}_{1}=-{\kappa }_{1}{\zeta }_{1}+{k}_{{\rm{P1}}}{x}_{1}\hfill\\ {\dot{\zeta }}_{2}=-{\kappa }_{2}{\zeta }_{2}+{k}_{{\rm{P2}}}{x}_{4}\hfill\\ {\dot{\zeta }}_{3}=-{\kappa }_{3}{\zeta }_{3}+{k}_{{\rm{I3}}}{x}_{5}\hfill\end{array}\right.$$

(11)

guarantees globally asymptotic closed-loop stability, if inequalities

$${\bar{k}}_{{\rm{P3}}} \, > \, \gamma -\sqrt{2\gamma {M}_{{\rm{S}}}{\varOmega }_{{\rm{S0}}}^{-1}}$$

(12)

$${\kappa }_{3} \, > \, {k}_{{\rm{I3}}}{\delta }_{\gamma }^{-1}{\left[1-{(2\gamma {M}_{{\rm{S}}})}^{-1}{\varOmega }_{{\rm{S0}}}{\delta }_{\gamma }^{2}\right]}^{-1}$$

(13)

$${\kappa }_{2} \, > \, \left[{(\gamma {M}_{{\rm{S}}})}^{-1}{\varOmega }_{{\rm{S0}}}{\bar{k}}_{{\rm{P3}}}^{2}+2\right]{k}_{{\rm{P2}}}$$

(14)

$${k}_{{\rm{D1}}} \, > \, \frac{2{G}_{{\rm{r}}}{P}_{0}{k}_{{\rm{D2}}}^{2}}{{\alpha }_{{\rm{R}}}{\varOmega }_{{\rm{S0}}}}\left[1+\frac{{\varOmega }_{{\rm{S0}}}}{\gamma {M}_{{\rm{S}}}}{k}_{{\rm{P3}}}^{2}+\frac{1}{2}{\left(\frac{{\kappa }_{2}}{2{k}_{{\rm{P2}}}}-\frac{{\varOmega }_{{\rm{S0}}}}{2\gamma {M}_{{\rm{S}}}}{\bar{k}}_{{\rm{P3}}}^{2}-1\right)}^{-1}{\left(1+\frac{1}{2{k}_{{\rm{D2}}}}+\frac{{\varOmega }_{{\rm{S0}}}{\bar{k}}_{{\rm{P3}}}}{2\gamma {M}_{{\rm{S}}}}\right)}^{2}\right]$$

(15)

are all well satisfied, where \({\bar{k}}_{{\rm{P3}}}={k}_{{\rm{P3}}}+1\), \({\delta }_{\gamma }=\gamma -{\bar{k}}_{{\rm{P3}}}\),and control gains kPi, kDj, kI3 and κi are all given postive constants (i = 1, 2, 3, and j = 1, 2).

Remark 1

By incorporating terms of x4 and its time-derivative into setpoint nr0, reactor control u1 in (11) can be implemented in a cascaded manner shown in Fig. 3. Steam temperature control u2 in (11) together with GP0 gives the final setpoint of helium flowrate, which is further controlled by regulating the rotation rate of helium blower. The steam temperature control u2 and helium flowrate control is also synthesized in a cascaded manner shown in Fig. 3. In addition, the inertia of helium blower can be compensated by enlarging gain kP3 in control law (11). As the difference between the dynamics of mHTGR module and that of other type reactor modules is limited, coordinated control (11) for a single mHTGR module is referenceable to the control other types of reactor modules.

Coordinate control method between two reactor modules

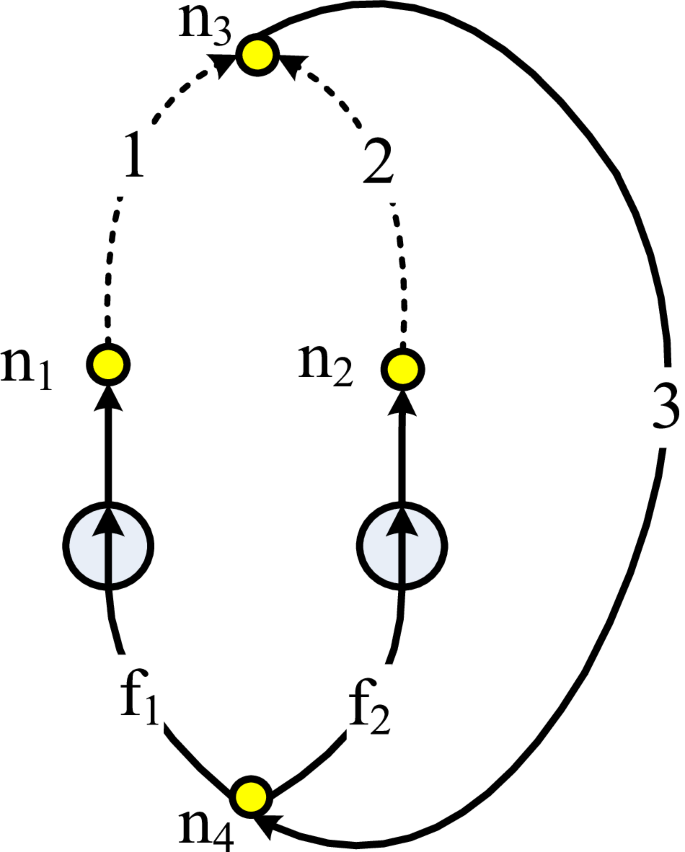

From Fig, 2, the two reactor modules are coupled by the common secondary loop system. The main coupling hydraulic dynamics in normal operation scenario can described by the fluid flow network (FFN) shown in Fig. 9, where branches f1 and f2 are the pump branches of #1 and #2 reactor modules composed of a feedwater pump and a high pressure heater (HPH), branches 1 and 2 are the feedwater the OTSG secondary sides of #1 and #2 modules respectively, and branch 3 is the fluid branch including the turbine, condenser, low pressure heaters (LPHs) and deaerator. The branches denoted by solid line constitute a tree of this FFN, while the branches denoted by dashed line are the links forming a co-tree. Nodes n1 and n2 represents the outlets of #1 and #2 HPHs respectively, node n3 is the inlet of common main steam header, node n4 represents the outlet of deaerator. The feedwater flowrates of #1 and #2 modules can be described by the flowrates of branches 1 and 2 respectively, and the main steam pressure can be represented by the pressure drop of tree branch 3.

n1, n2, n3 and n4: nodes, f1 and f2: fan branches, branches 1 and 2: links, branches 3, f1 and f2: tree branches.

Based on the fluid dynamics of pipelines, the flowrates in branches 1, 2 and 3 can be governed by

$${\bf{L}}\dot{{\bf{Q}}}+{\bf{R}}{{\bf{Q}}}_{{\rm{D}}}={\bf{H}}$$

(16)

where Q = [Q1 Q2 Q3]T, H = [H1 H2 H3]T, QD = [Q12 Q22 Q32]T, L=diag([L1 L2 L3]T), R=diag([R1 R2 R3]T), Qi, Hi, Ri and Li are respectively the flowrate, pressure-drop, fluid resistance and fluid inertia of branches i (i = 1, 2, 3). In addition, the pressure-drops of pump branches fk (k = 1, 2), i.e. Hfk can be given by

$${H}_{{\rm{f}}k}=-{H}_{{\rm{d}}k}+{R}_{{\rm{f}}k}{Q}_{k}$$

(17)

where Hdk is the pressure header provided by #k pump being proportional to the square of rotation rate, Rfk is the resistance coefficient of pump branch fk, k = 1, 2.

By applying Kirchhoff’s current law (KCL) to node n3, it can be seen that

$${Q}_{3}={Q}_{1}+{Q}_{2}$$

(18)

giving that

$${\dot{Q}}_{3}={\dot{Q}}_{1}+{\dot{Q}}_{2}.$$

(19)

Substitute (16) to (19),

$${L}_{3}^{-1}{H}_{3}={L}_{3}^{-1}{R}_{3}{({Q}_{1}+{Q}_{2})}^{2}+\mathop{\sum }\limits_{i=1}^{2}{L}_{i}^{-1}({H}_{i}-{R}_{i}{Q}_{i}^{2})$$

(20)

Then, apply Kirchhoff’s voltage law (KVL) to the fundamental loops,

$$\begin{array}{cc}{H}_{k}+{H}_{3}+{H}_{{\rm{f}}k}=0,& k=1,2.\end{array}$$

(21)

From (17), (20) and (21), one can see that

$$\begin{array}{cc}{H}_{k}={H}_{{\rm{d}}k}-{R}_{{\rm{f}}k}{Q}_{k}-{H}_{3},& k=1,2,\end{array}$$

(22)

$${L}^{-1}{H}_{3}={L}_{3}^{-1}{R}_{3}{Q}_{3}^{2}+\mathop{\sum }\limits_{k=1}^{2}{L}_{k}^{-1}({H}_{{\rm{d}}k}-{R}_{{\rm{f}}k}{Q}_{k}-{R}_{k}{Q}_{k}^{2})$$

(23)

where L = L1L2L3/(L1L2 + L2L3 + L3L1).

From (16), (22) and (23), the FFN dynamics is governed by nonlinear differential-algebraic system (DAS)

$$\left\{{\begin{array}{c}{{\bf{L}}}_{{\rm{c}}}{\dot{{\bf{Q}}}}_{{\rm{c}}}={{\bf{H}}}_{{\rm{d}}}-{{\bf{R}}}_{{\rm{f}}}{{\bf{Q}}}_{{\rm{c}}}-{{\bf{R}}}_{{\rm{c}}}{{\bf{Q}}}_{{\rm{cD}}}-{H}_{3}{\mathbf{\eta }},\hfill\\ {H}_{3}=L{L}_{3}^{-1}{R}_{3}{Q}_{3}^{2}+\mathop{\sum }\limits_{k=1}^{2}L{L}_{k}^{-1}({H}_{{\rm{d}}k}-{R}_{{\rm{f}}k}{Q}_{k}-{R}_{k}{Q}_{k}^{2}),\end{array}}\right.$$

(24)

where Qc = [Q1 Q2]T, Hd = [Hd1 Hd2]T, QcD = [Q12 Q22]T, Rc = diag([R1 R2]T), Rf = diag([Rf1 Rf2]T), Lc = diag ([L1 L2]T), η = [1 1]T. From Fig. 1, the operation of two reactor modules can be decoupled if the feedwater flowrates are well regulated, and the main steam pressure is firmly stabilized, giving that the coordinated control between two modules is essentially the flowrate-pressure joint control of the FFN shown in Fig. 9. The flowrate-pressure joint control design can be further transferred to the control design of nonlinear DAS (24), and the following proposition gives an adaptive control for system (24) with the sufficient condition for globally asymptotical closed-loop stability.

Proposition 2

Consider nonlinear DAS (24) with Qcr = [Q1r Q2r]T and H3r being defined as the setpoints of Qc and H3 respectively. The joint controller

$$\left\{{\begin{array}{c}{{\bf{H}}}_{{\rm{d}}}={\hat{{\bf{H}}}}_{{\rm{dr}}}-{{\mathbf{\Gamma }}}_{{\rm{d}}}{{\bf{Q}}}_{{\rm{ce}}} \hfill \\ {R}_{3}={\hat{R}}_{3{\rm{r}}}-{Q}_{{\rm{3r}}}^{-2}{\varGamma }_{{\rm{a}}}{H}_{3{\rm{e}}}\end{array}}\right.$$

(25)

with \({\hat{{\bf{H}}}}_{{\rm{dr}}}\) and \({\hat{R}}_{3{\rm{r}}}\) given by adaptation law

$$\left\{\begin{array}{c}{\dot{\hat{{\bf{H}}}}}_{{\rm{dr}}}=-{{\mathbf{\Pi }}}_{{\rm{d}}}{{\bf{Q}}}_{{\rm{ce}}} \hfill\\ {\dot{\hat{R}}}_{{\rm{3r}}}=-{\varPi }_{{\rm{a}}}{Q}_{3{\rm{r}}}^{2}{\varOmega }_{3}^{-1}{H}_{3{\rm{e}}}\end{array}\right.$$

(26)

provides globally asymptotic stability to setpoints if inequality

$${\varGamma }_{{\rm{a}}} \, > \, {\varOmega }_{3}^{-1}{L}_{3}^{2}{{\mathbf{\eta }}}^{{\rm{T}}}{{\bf{L}}}_{{\rm{c}}}^{-1}({{\mathbf{\Gamma }}}_{{\rm{d}}}+{{\bf{R}}}_{{\rm{f}}}+{{\mathbf{\Omega }}}_{{\rm{c}}}+{{\mathbf{\Lambda }}}_{{\rm{a}}}){{\bf{L}}}_{{\rm{c}}}^{-1}{\mathbf{\eta }}$$

(27)

is well satisfied, where Qce = Qc–Qcr, H3e = H3–H3r, Q3r = Q1r + Q2r, Ωi = Ri(Qi+Qir) with i = 1, 2, 3, Ωc = diag([Ω1, Ω2]T), both Γa and Πa are given positive constants, and Γd, Πd and Λa are given positive-definite diagonal matrices.

Remark 2

It can be seen from (25) that the pressure header provided by #k pump are used to regulate the feedwater flowrate of #k reactor module (k = 1, 2), while the fluid resistance of tree branch such as the regulating value of turbine is applied for stabilizing the main stream pressure. Submit (26) to (25),

$$\left\{\begin{array}{c}{{\bf{H}}}_{{\rm{d}}}=-{{\mathbf{\Gamma }}}_{{\rm{d}}}{{\bf{Q}}}_{{\rm{ce}}}-{{\mathbf{\Pi }}}_{{\rm{d}}}{\int }_{0}^{t}{{\bf{Q}}}_{{\rm{ce}}}(\tau ){\rm{d}}\tau,\hfill \\ {R}_{3}=-{Q}_{3,{\rm{r}}}^{-2}{\varGamma }_{{\rm{a}}}{H}_{3{\rm{e}}}-{\varPi }_{{\rm{a}}}{\int }_{0}^{t}{Q}_{{\rm{3r}}}^{2}{\varOmega }_{3}^{-1}{H}_{3{\rm{e}}}(\tau ){\rm{d}}\tau,\end{array}\right.$$

(28)

showing that the adaptive control laws are essentially distributed proportional-integral (PI) control algorithms. The two PI laws in (28) form the feedwater flowrate controllers of two modules and the main steam pressure controller shown in Fig. 3. Since the multiple reactor modules in a multi-modular NPP are coupled together by the common secondary FFN, coordinated control (28) can be also applicable to the coordination between all types of reactor module generating superheated steam.