Sample materials

Materials used for the preparation of metallic samples in this work were purchased from Goodfellow (UK) or the Joint Research Centre (JRC, Geel, Belgium), Institute for Reference Materials and Measurements (IRMM). Wherever possible, samples in disk/foil form were made, which was the case for Mg, Ce, Zr, Ni, Al. For samples of Se, Ge, Te it was not possible to create samples in disk form on account of the brittleness of the materials, and material fragments were used instead. In the case of Na, the sample material used was NaF powder, purchased from Sigma Aldrich, which was encapsulated in polyethylene foil. Table 5 reports the sample materials used in the present work, the nominal sample dimensions and the typical sample mass.

\(\alpha\) heating in neutron filters

The boron based neutron filters used in the present work were manufactured by hot pressing (\(\hbox {B}\hbox {N}\)) and electron beam machining (\(\hbox {B}_4\hbox {C}\) and \(^{10}\hbox {B}_4\hbox {C}\)). The filters were cylindrical with an internal cavity 5 mm in diameter and height. The filter wall thickness (top and bottom, as well as cylindrical) was 4 mm. Figure 5 displays the actual filters used in this work.

Boron based neutron filters used in this work. From left to right: boron nitride (\(\hbox {B}\hbox {N}\)), natural boron carbide (\(\hbox {B}_4\hbox {C}\)) and enriched boron carbide (\(^{10}\hbox {B}_4\hbox {C}\)).

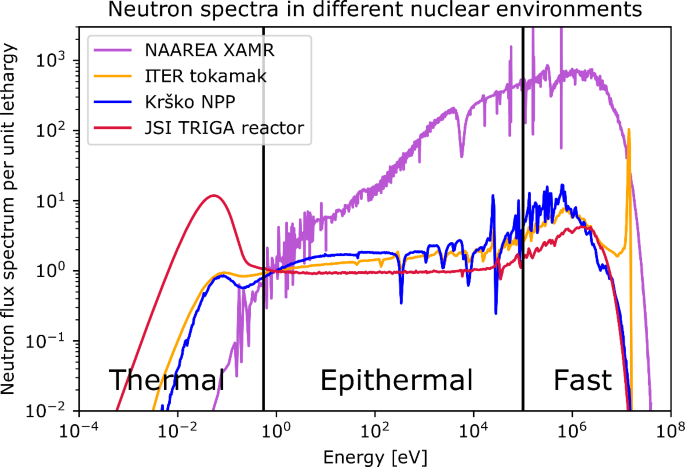

In this work, \(\alpha\) particle heating originating from \(^{10}\)B\((n,\alpha )^7\)Li reactions occurring in boron-based neutron filters posed an important constraint for the irradiations, as several sample materials had relatively low ignition temperatures (e.g. Ce, Te, Mg). In order to mitigate the risk of sample ignition during irradiation, prior to the experimental campaign we performed measurements of the temperature during irradiation inside a \(^{10}\hbox {B}_4\hbox {C}\) neutron filter (most restrictive case). The filter was equipped with a small T-type thermocouple, made by silver-soldering 0.003 inch (approx. 0.08 mm) diameter teflon-insulated wires of copper and constantan. The filter was irradiated in the F26 irradiation channel of the JSI TRIGA reactor (close to the Pneumatic Tube, in position F24). Figure 6 displays plots of the measured temperature and reactor power vs. time, as well as a top view of the JSI TRIGA reactor core, highlighting the F24 irradiation channel used in the present work. Based on the measurements, we decided to limit the power level to 50 kW for the experimental campaign, resulting in a maximal expected temperature within the \(^{10}\hbox {B}_4\hbox {C}\) filter between \(80^{\circ }\hbox {C}\) and \(100^{\circ }\hbox {C}\). No temperature-related issues were encountered in the experimental campaign.

Left: 3D render of JSI TRIGA reactor core, highlighting the experimental locations used in the present work. Right: plots of the measured temperature in the \(^{10}\hbox {B}_4\hbox {C}\) filter and reactor power vs. time.

Sample irradiation and measurement

Samples were weighed using an analytical balance with 10 \(\upmu\)g precision. For each material we irradiated 4 samples, one bare and three inside boron-based filters. Irradiations were performed in the F24 position in the core of the JSI TRIGA reactor, equipped with a pneumatic sample transfer system. The irradiation position is commonly denoted as Pneumatic Tube (PT). The irradiations were performed by placing the bare samples or samples contained within boron-based filters into standard polyethylene rabbit tubes. The filters were carefully wrapped in a small amount of paper to center them within the rabbit tubes.

The irradiations were performed using an electronically controlled pneumatic sample transfer system developed and manufactured in-house19. The irradiation, cooling and measurement times were chosen appropriately, depending of the half-lives of the reaction products. For the aluminium samples, the irradiation, cooling and measurement times were the shortest, of the order of a few minutes, as the measured reaction product (\(^{28}\)Al) has the shortest half-life −2.245 min. The longest irradiation, cooling and measurement times were, respectively, two hours, 107 days and 7 days in case of longer-lived activation products (\(^{64}\)Zn, with a half-life of 243.93 days, \(^{95}\)Zr, with a half-life of 64.032 days and \(^{141}\)Ce, with a half-life of 32.511 days). In order to compensate for the lower induced activities in samples irradiated under filter, longer irradiation times were specified, compared to irradiations of bare samples.

For the measurements, a p-type high purity germanium (HPGe) detector was used, manufactured by ORTEC (model GEM-P4 PLUS-S) with a relative efficiency of 54.1% at 1.33 MeV, operated by an ORTEC DSPEC 502 data acquisition system, located in the gamma spectrometry laboratory adjacent to the reactor.

Bare vs. filtered reaction rate ratios, as defined in Eq. (3) were computed from the fitted peak areas in the measured gamma spectra, the sample masses, and the timing information, using the JSI-developed SPCACT code. The code calculates the combined uncertainties in the reaction rate ratios by propagation of the uncertainties in all the input data: the sample masses, the irradiation, cooling and measurement times and the fitted peak areas.

In general, the main sources of uncertainty in the determination of absolute reaction rates/saturated activities through gamma spectrometry measurements are the uncertainties in the peak areas \(N_p\) and the detection efficiency. Other correction factors may be significant and required, e.g. due to gamma self-absorption in the sample materials, coincidence correction factors; the uncertainties in these correction factors contributing to the uncertainty in the final result. In the present work, a pure relative method was used to determine the reaction rate ratios R, in order to minimize the uncertainty in the experimental results due to the numerous sources mentioned above. This approach is the same as adopted in (relative) Neutron Activation Analysis (NAA), a nondestructive analytical technique enabling measurements of wide ranges of concentrations for multiple elements, where the measured elemental concentrations in investigated materials are determined on the basis of measurements of irradiated material samples and specially prepared co-irradiated standards. Several conditions have to be met in order for the quantities needed in the determination of absolute reaction rates, to cancel out in the determination of reaction rate ratios. Corrections due to potentially different concentrations of the target isotope in the bare and filtered samples are assumed not to be required if all samples are prepared from the same batch of material. The neutron flux is assumed to be constant for the bare and filtered irradiations; this aspect was monitored during the experimental campaign. Several correction factors originate from the gamma spectrometry measurements. The detection efficiency (needed for absolute reaction rate/activity determination, usually calibrated by means of calibration sources with certified activity levels) can cancel out in Eq. (3) if the samples are measured with the same detector, using the same measurement geometry, and the ratios are computed for measured peak areas for the same gamma energy. It is worth noting that usually there are multiple gamma ray energies emitted by activation products. In the present work, ratios were computed for all the dominant gamma ray energies of the product isotopes, giving rise to multiple entries in Table 3 (one entry per gamma ray energy). Corrections due to coincidences in the measurements also cancel out if the same conditions are met. Corrections due to gamma self-absorption in the samples can also cancel out if the samples have the same macroscopic properties (density and thickness). If the above conditions are met, any uncertainty in the correction factors which cancel out in Eq. (3) does not propagate to the final result, the experimental reaction rate ratios R.

Neutron flux monitoring

Monitor samples of Al-0.1% Au alloy were used to monitor the neutron flux during the individual irradiations. Foils approximately 5 mm in diameter were prepared, weighted and packed in polyethylene film, and attached on the inside of the rabbit tube caps. The monitor samples were at approximately 5 cm from the neutron filters within the rabbit tubes. The measurements of the monitor samples for bare irradiations showed excellent consistency, the standard deviation of the reaction rates amounting to 1.3%. The measurements of the monitor samples for filtered irradiations also showed excellent consistency, the standard deviation being 2.3%, however the absolute reaction rate values were consistently lower than for the bare irradiations, on average around 4.3%. This is attributed to the presence of the neutron filter, causing a local depression in the neutron flux.

A miniature fission chamber was also used as an online relative monitor of the neutron flux. It was inserted in measurement position (MP) no. 10, in the vicinity of the F24 position highlighted in Fig. 6. The fission chamber was manufactured by the Instrumentation, Sensors and Dosimetry Laboratory of CEA—Cadarache (serial number 2289) and had a \(^{235}\)U deposit with an activity of 40 Bq. It was installed in an aluminium guide tube inserted into the reactor core from the platform level. The bottom of the guide tube was located 800 mm from the top of the top reactor grid plate, the fission chamber was lifted approximately 450 mm from the bottom in the guide tube, and its position was maintained throughout the campaign. The fission chamber was operated in current mode. The average measured currents during the irradiations at the reactor power level of 50 kW remained stable throughout the campaign, their standard deviation being 0.6%, demonstrating an excellent power stability. Figure 7 displays plots of the fission chamber current and reactor power vs. time during the experimental campaign, as well as the measured specific saturation activities for the \(^{197}\)Au\((n,\gamma )\) reaction used as a monitor, in units of reactions per second per target atom.

Plots of the reactor power vs. time, obtained from the JSI TRIGA reactor instrumentation and the monitor fission chamber current vs. time for the whole experimental campaign.